As part of the master program Supply Chain Management and together with the Institute for Production Management at Vienna University of Economics and Business (WU), two students developed a framework to measure the advantages of digitalization. The framework helps customers to quantify the impact on savings the field service management software Workheld can yield for their company.

The framework

The developed framework gives companies the chance to include all processes, tasks and use cases which are incorporated in Workheld and tries to put a numeric value on these. Hence, all processes need to be outlined by the company beforehand.

The framework asks for basic data like the project name, the start date, the internal personnel costs, and the monthly working hours. After that the company has to insert all costs related to the implementation of the new software.

IT costs:

- Software costs

- Hardware and equipment costs

Business costs:

- Consulting costs

- Internal personal costs

- Training costs

- Risk costs

After that quantitative benefits have been identified. Then the framework asks to insert the time for each process before the implementation of Workheld, and after. The calculated difference shows the potential savings the company can realize with the implementation of Workheld.

Impact for a medium-sized company

An example for a medium-sized company (67 employees were assumed) in the mechanical engineering industry shows the advantages Workheld has to offer.

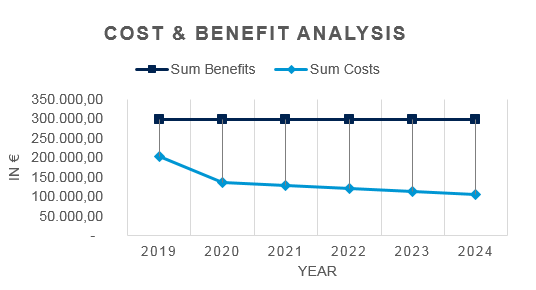

The graph below shows that the Workheld solution already pays off in the implementation year. The savings grow from 94,631 € in the first year up to 191,791 € in the sixth year. In sum, the Workheld solution generates savings of 979,618 € over a six-year horizon.

The chart also shows that the benefits of digitisation are increasing year by year. The comparatively low figure for the first year is due to the assumption that even a user-friendly system like Workheld requires a period of acclimatisation before all the benefits become apparent. It is also clear that the costs for hardware, training and other time expenditure are negligible in relation to the actual benefits of Workheld.

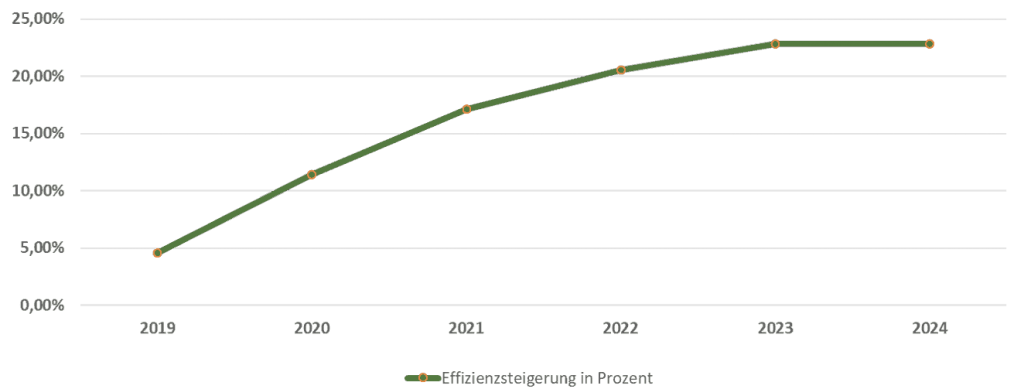

Working more efficiently with Workheld

The savings are primarily due to increased efficiency. Digitization with Workheld allows faster planning, execution and documentation of assembly, service and maintenance processes. Coordinators benefit from planning tools and integrated asset, material and tool management. Above all, technicians save time in documentation and report generation. In the case of an interface connection to an existing ERP system, a serious part of the administrative work is also eliminated.

Another advantage of the digitalization of assembly, service and maintenance is the more transparent processes and up-to-date order data. This also helps to avoid costly misunderstandings and errors.

Would you also like to know how much you can save with Workheld? – Then contact us now!

Thanks to Milena Kölbl and Anna Melina Wilms from the Vienna University of Economics and Business Administration (WU) for their commitment and friendly cooperation.