SAP ERP and Workheld – two software solutions – one match made in heaven. The user-friendly cloud solution Workheld can be individually customized for your maintenance company and your needs!

Compatibility of SAP & Workheld

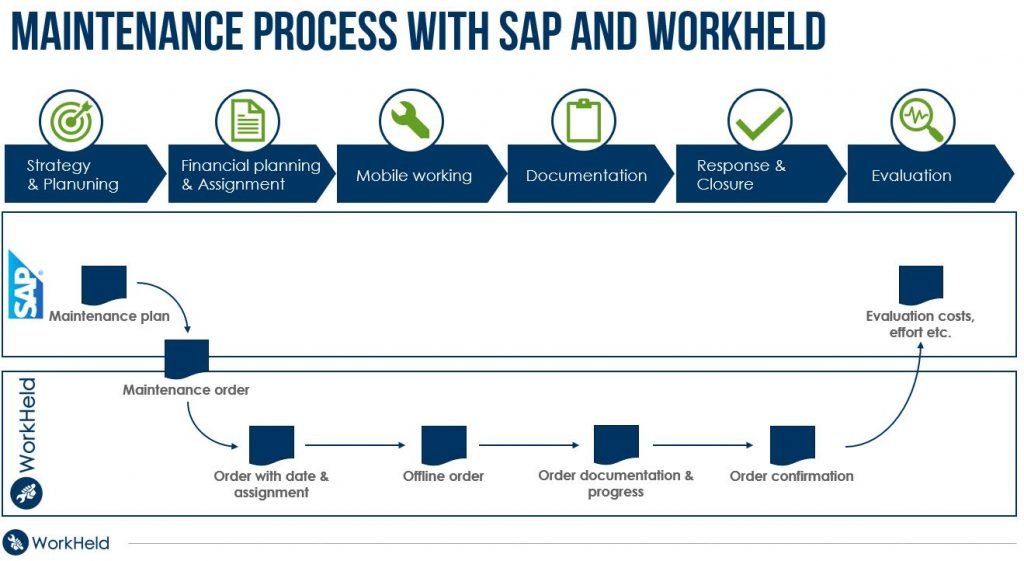

With the SAP ERP software solution, you can generate and manage your maintenance orders automatically. The preparation of these orders for technicians and coordinators usually seems very complex and the software is only easy to handle for experts. With the additional use of Workheld you get the best of both software solutions.

Once the order has been created in the SAP system, it can be processed quickly and easily with Workheld and its individually adaptable features. You can also synchronize the current order status at any time and update it. After the order is completed, a PDF report can be generated from the technicians’ documentation at the push of a button and signed on the tablet. At the same time, the recorded data is transferred to the SAP system and ensures complete transparency.

With Workheld order planning becomes a piece of cake

Shift and job planning has never been so easy as with Workheld! Assign your technicians, necessary tools and equipment to different work orders – fast and easy, via drag and drop.

To avoid a double assignment in advance, you can use the availability check to check in a few clicks whether or not the selected employee is assigned a different work order at the planned time.

With the Team Planner you also have the possibility to create the weekly work schedule of all employees via drag & drop and present it in the briefing.

Complete transparency – anytime and anywhere

The status dashboard shows you the progress and status of projects, assignments and work orders at a glance. Status synchronization by technicians in the field provides immediate feedback to SAP and continuously updated information to the coordinator. Overdue and delayed orders are highlighted so that you can easily check where follow-up is necessary.

Recorded defects and problem messages are displayed prominently in the status overview to ensure that a quick response is possible. If the defect is created in the course of a work order or individual work step to which an asset has also been assigned, it is automatically linked to the asset history and can be called up at any time via the asset overview. In this way, over time it becomes possible to gain important insights into common problems with certain plant components.

Predictive resource planning through extensive data analysis – how Workheld supports you

With Workheld and its features, terms such as predictive resource management and proactive quality assurance are no longer a thing of the past. After the job is done and the data has been synchronized with the SAP system, machine data and documentation can be evaluated directly in Microsoft Power BI. This comprehensive data analysis provides a basis for predictive maintenance and makes a detailed cost evaluation of work orders possible.

Messer counts on Workheld and SAP

Messer Austria GmbH, one of the world’s leading industrial gases companies, relies on the cooperation of SAP and Workheld for the digitalization of its maintenance processes.

“SAP ERP and Workheld are a powerful combination. SAP’s functionalities in the area of maintenance are very extensive. In combination with a user-friendly tool for the technician, a lot more can be achieved,” says Christine Geier, Tablet Solutions COO and Product Manager of Workheld.

Thanks to the individual adaptability of the Workheld features, the cloud solution could be perfectly matched to the wishes and needs of the company, guarantees an excellent cooperation.

Interested? Find out if Workheld is the right solution for you – contact us now and we will be happy to discuss your requirements with you!