With the features asset management, tool management and defect management, Workheld gives you access to the right information and documentation anytime and anywhere – even without an active internet connection.

Asset management & asset documentation – everything at a glance

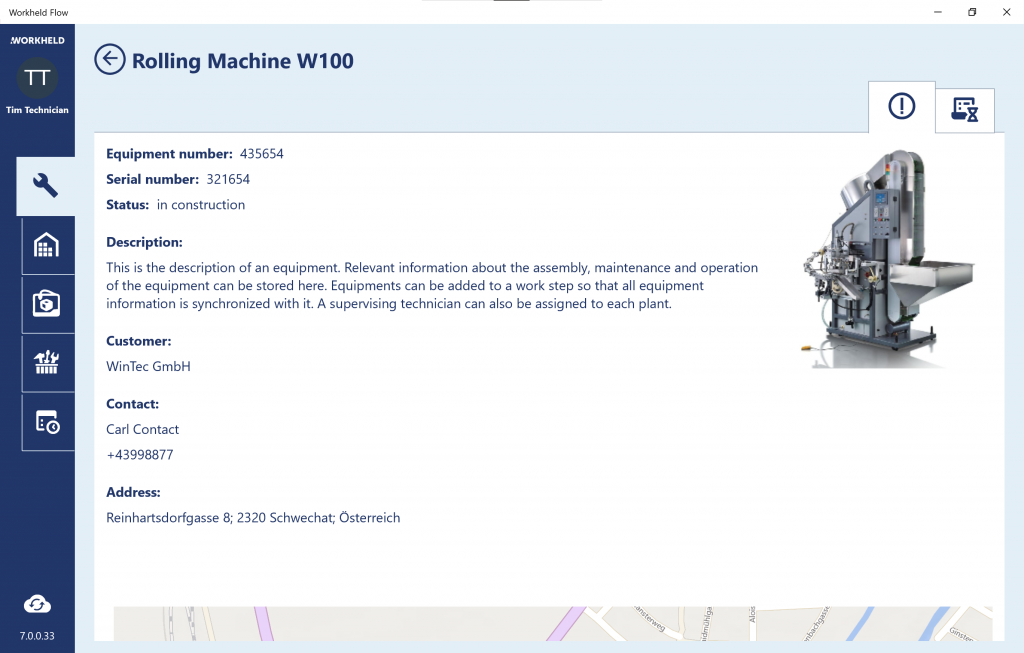

Documenting, finding and retrieving all relevant information about assets has never been easier than with Workheld! With Workheld’s asset management you can easily create new assets and immediately assign to a specific work order or individual work step by drag & drop. This gives technicians immediate access to detailed information about the status of the asset, the exact location, the specifics of the asset and the contact person.

The technicians’ documentation is linked to a particular asset via the asset management feature. This enables you to trace precisely when, where and how work was done on a system. The asset history shows you in detail which parts were replaced, which values were recorded during the last check, or if defects have occurred recently. Based on this data, you can evaluate and determine how much working time was invested in the maintenance of a particular type of system or how often repairs had to be done.

With Workheld you have the right information at your fingertips, anytime and anywhere.

Tool management – everything about the ideal tool and much more

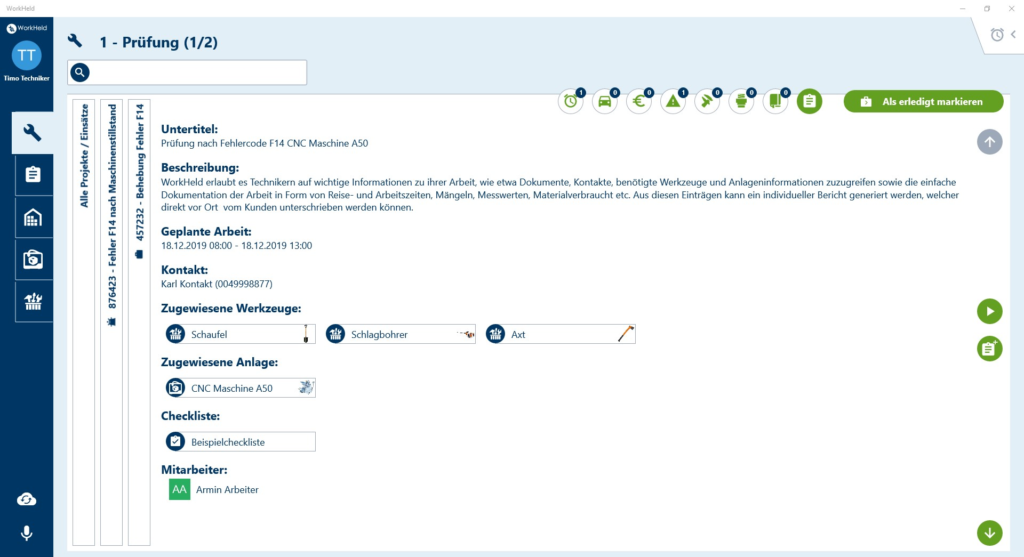

With Workheld you have the possibility to attach the necessary tools for the planned work order directly by drag & drop, to the order or to the individual work step. This way technicians know exactly that they need a specific measuring device, for example, to carry out a inspection. To eliminate time-consuming questions in advance, you can also add all important information on handling or the necessary safety precautions to the tools.

If a tool needs to be maintained or is not available for another reason, you can retrieve this information via the tool status. With the tool overview, every technician can access all relevant information about a specific tool, even if he is not currently assigned to a project with exactly this tool.

Thanks to the tool management, all necessary information is always and everywhere available.

Fast problem description, problem documentation & problem solving through defect management

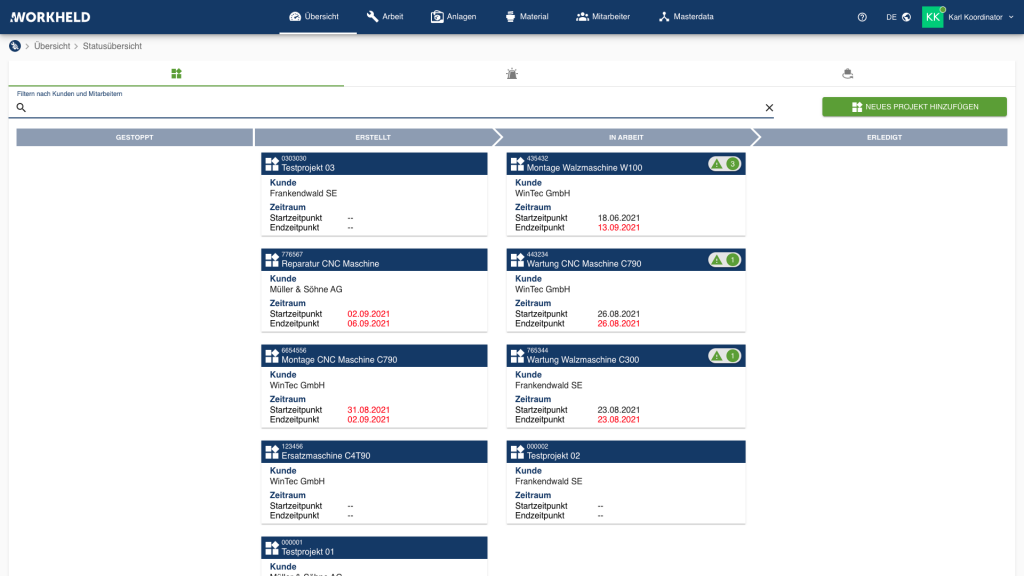

With the help of the defect management, technicians can quickly and easily document defects or problems, including photos and a detailed description of the defect, the time lost and the materials affected. Technicians can choose from pre-defined deviation types and defect categories and, of course, adapt them individually. A description of the defect, a provisional solution, a general comment, the order number, the affected material and model and the time loss can be specified.

To ensure that technicians can easily describe and explain even complex problems, it is possible to mark the defect with markers so that it can be immediately identified where exactly the problem lies. Defects can also be documented with our intelligent voice assistant. The possibility of voice input provides more safety and a more efficient working process for the technicians in the field.

Saved defects are prominently displayed in the status overview to ensure that you can react as quickly as possible. If the defect is created in the process of a work order or individual work step to which an asset has also been assigned, the value is automatically linked to the asset history and you can call it up at any time via the asset overview. In this way, over time, useful insights into common problems with certain asset components also become apparent.

Workheld takes you one step further towards digitalization of the maintenance process and ensures that the right information is always available.