SAP ERP and Workheld – two software solutions – one match made in heaven. The user-friendly cloud solution Workheld can be individually customized for your maintenance company and your needs!

Compatibility of SAP & Workheld

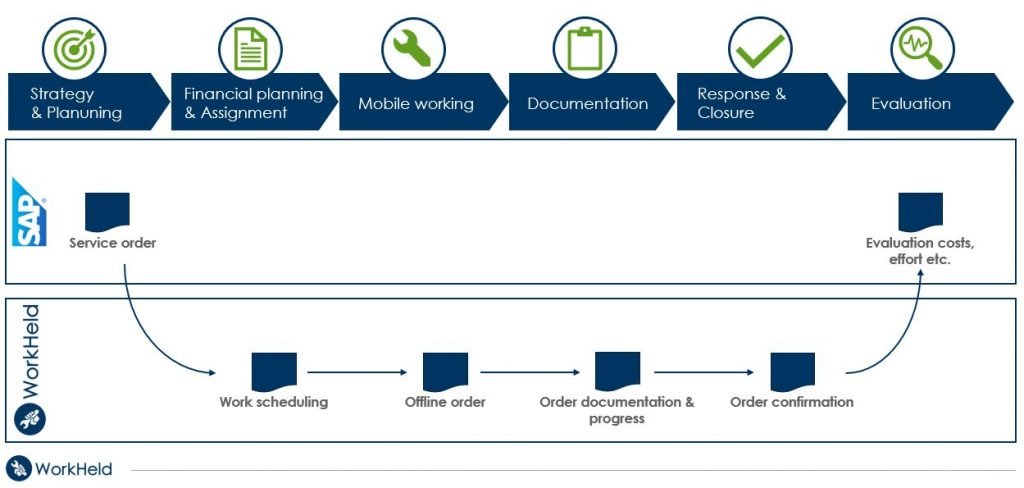

With the SAP ERP software solution, you can create and manage your service orders, but the preparation of these orders usually seems very complex and the software is only easy to handle for experts. By adding Workheld you get the best of both software solutions: the power of SAP and the user interface of Workheld!

Once the order has been created in the SAP system, it can be processed quickly and easily with Workheld and its individually adaptable features. Keep an overview of the order status at all times. Field technicians can easily synchronize it at any time. After finishing the order, a PDF report can be generated from the documentation at the push of a button and signed by the customer directly on site. At the same time, the saved data is transferred to the SAP system, ensuring complete transparency.

With Workheld order planning & resource planning becomes a piece of cake

With the Team Planner you have the possibility to create the weekly work schedule of all employees via drag & drop and present it in the briefing.

Workheld’s material management allows technicians to maintain an inventory to know exactly what resources are available on site. If material consumption is documented, the inventory is automatically updated in the background. Controller can also access the inventory to see immediately which technician is using a particular spare part, which is needed to repair a particular piece of equipment, for example.

Customer satisfaction through increased reaction speed & transparency in the work process

The more efficient and faster the process from order placement to order completion, the more satisfied your customer. After receiving the order from the customer, you can start immediately with the resource planning via drag & drop. The possibility to add checklists, pictures and sketches to work orders makes it easier to complete the task. Also the possibility to document comments and defects and to synchronize them at the same time ensures a transparent and efficient working process.

The status dashboard ensures that you can always tell the customer exactly what the current status of the order is. This allows you to see at a glance the progress of projects, assignments and work orders. After each synchronization by the technician in the field, the information is sent and updated simultaneously to the coordinators in the office.

Digital reports – digital signature – real liquidity increase

After finishing the order, the technician can generate a PDF report from his entire documentation with just a few clicks. The digital report includes travel times, working hours, completed tasks and material used. The recorded data is simultaneously transferred to the SAP system. This allows the orders to be evaluated and completed in terms of costs, which provides the basis for invoicing. The faster invoicing ensures that the turnover of receivables is increased, thus enabling an early liquidity increase.

Messer counts on Workheld and SAP

Messer Austria GmbH, one of the world’s leading industrial gases companies, relies on the cooperation of SAP and Workheld for the digitalization of its maintenance processes.

“SAP ERP and Workheld are a powerful combination. The functionalities of SAP in the service area are very extensive. In combination with a user-friendly tool for the technician, a lot more can be achieved,” says Christine Geier, Tablet Solutions COO and Product Manager of Workheld.

Thanks to the individual adaptability of the Workheld features, the cloud solution could be perfectly matched to the wishes and needs of the company, guarantees an excellent cooperation.

Interested? Find out if Workheld is the right solution for you – contact us now and we will be happy to discuss your requirements with you!