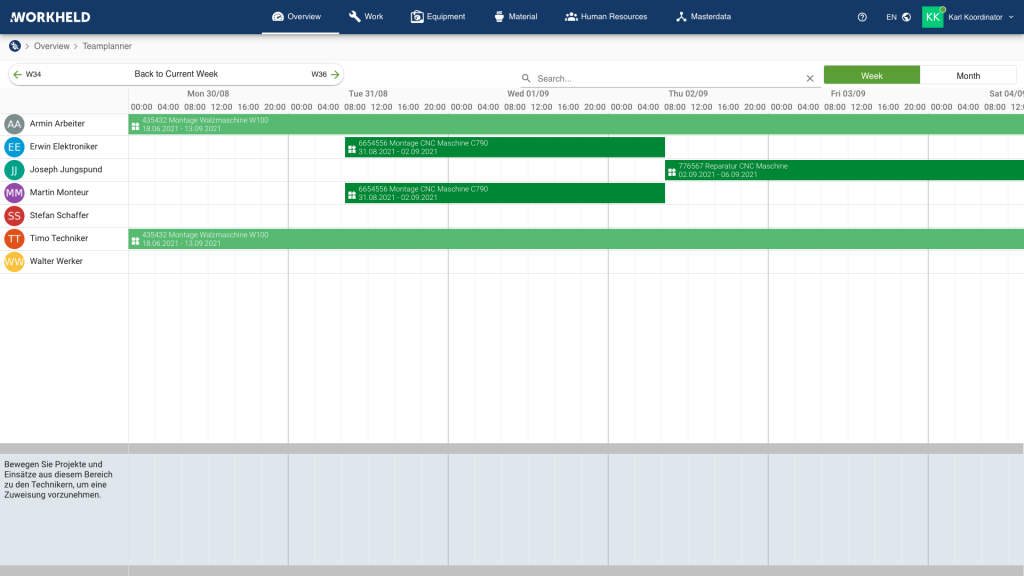

Transparent order planning – simple resource control

With Workheld’s transparent scheduling and order planning you always know about all technicians and tools used. Because with Workheld you can add technicians as well as necessary tools and assets to work orders or individual work steps by drag & drop. This allows you to quickly and easily track which technicians are in the field and which tools and assets are currently unavailable or under repair or service. This transparent job scheduling makes it easy to control resources in your customer service organization or assembly company.

Planning resources through complete transparency

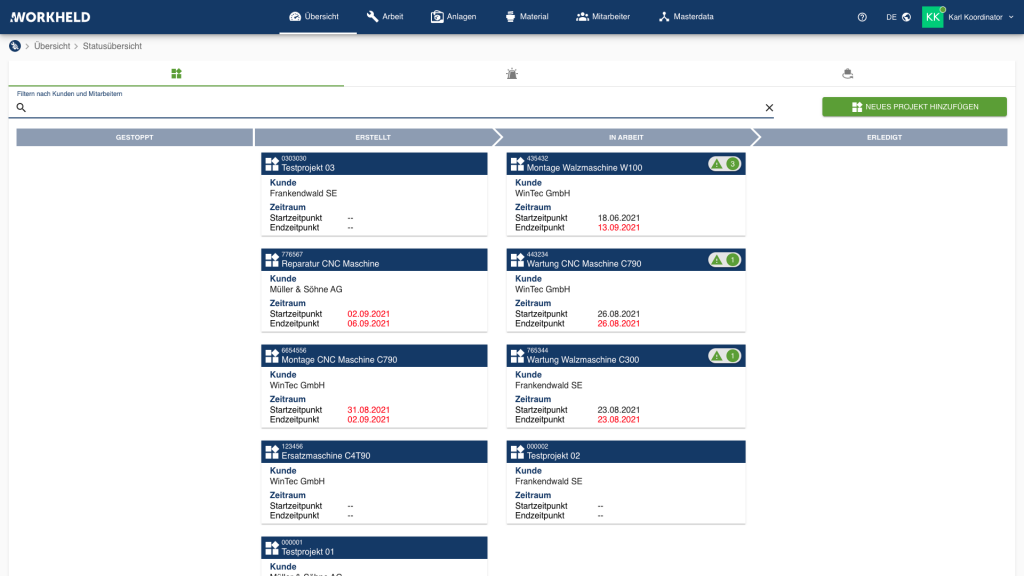

The status dashboard allows you to see at a glance the progress of projects, assignments and work orders. You will also be warned if, for example, a work order should already be in progress, but no work has been done yet. This allows you to successfully plan and control resources.

In the status overview, saved defects are displayed prominently to ensure that you can react as quickly as possible with the right means. If the defect is created in the course of a work order or individual work step to which an asset has also been assigned, the value is automatically linked to the asset history and can be called up at any time via the asset overview. Over time, useful insights into common problems with certain asset components become apparent. In this way, you can also plan future problems in advance and counteract them early on with the right means and resources.

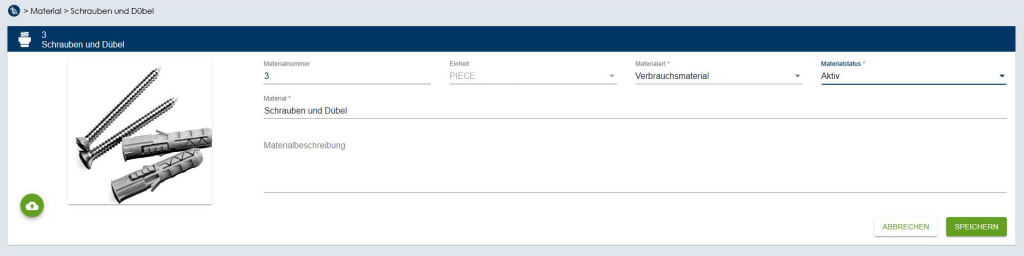

Material stock, consumption, & purchase at a glance

Workheld’s materials management allows technicians to maintain an inventory to know exactly what resources are available on site. If material consumption is documented, the inventory is automatically updated in the background. You can also access the inventory to see immediately which technician is using a particular spare part, for example, one that is needed to repair a particular asset. In addition, the quantity of resources used per work order can be analyzed, which enables cost-based evaluation, resource control and predictive resource planning.

The ordering of consumables and spare parts is also included in Workheld’s material management. Here you can order spare parts directly to the work order and document the use of spare parts so that it is clear which, customers must be invoiced for the materials. By digitizing your customer service or assembly you can plan your material stock in advance and control it in real time.

Customer Service 4.0: Quality assurance and predictive resource planning through extensive data analysis

With Workheld and features such as material management, asset management and status management, terms such as predictive resource management and advanced quality assurance are no longer a thing of the past. After completion of the work order, machine data and documentation can be evaluated directly in Microsoft Power BI. This comprehensive data analysis provides a basis for predictive maintenance.

Workheld reduces machine downtime through efficient maintenance planning and helps to save costs. With Workheld you can ensure complete transparency and predictive resource planning throughout the service and assembly process.